Steam for Tomorrow

Emission-Free Steam Supply for Hygiene Processes – Flexibly Scalable and Intelligently Controlled

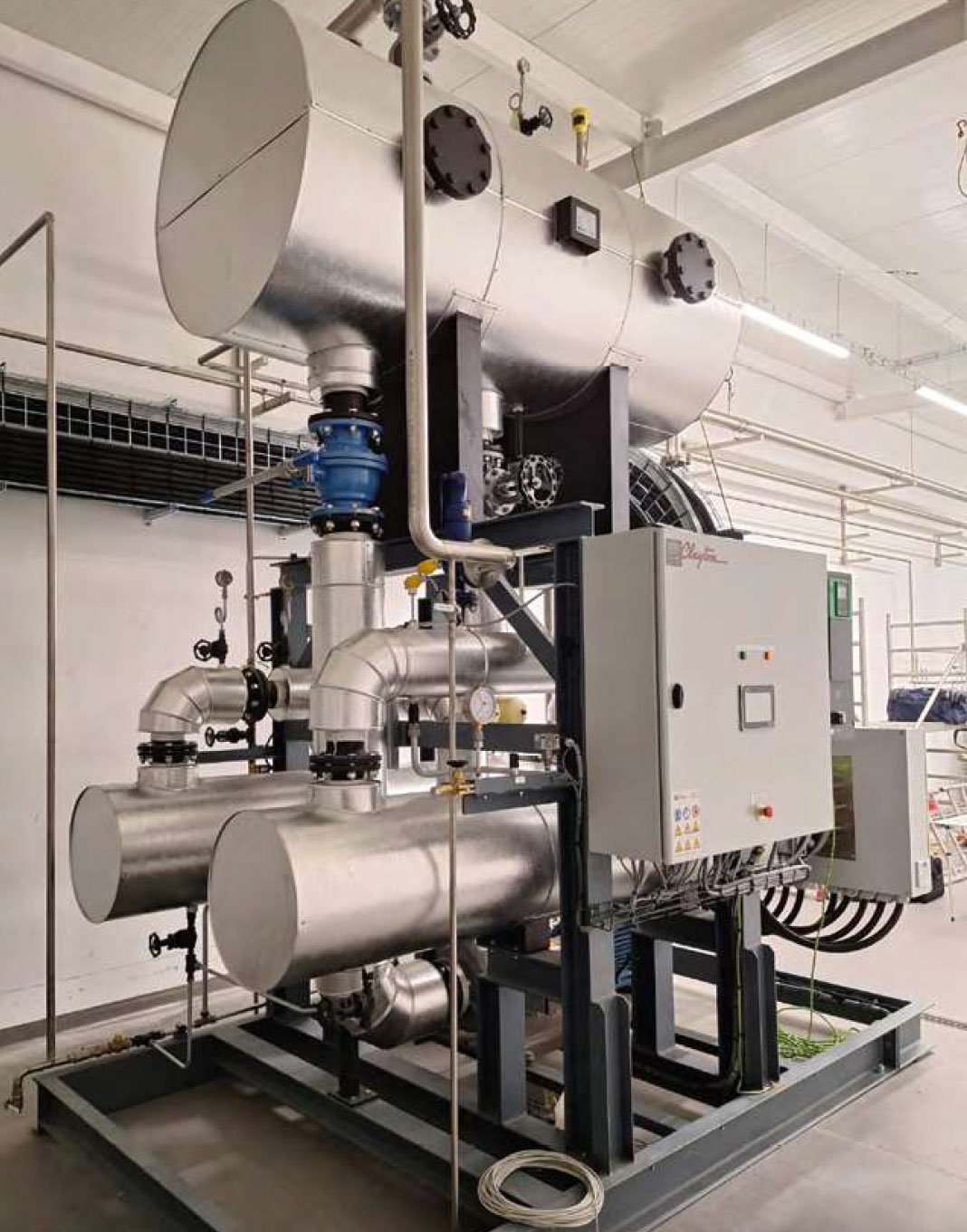

The beverage industry imposes high demands on hygiene, energy efficiency, and process control. Clayton’s fully electric steam series offers a forward-looking solution: it delivers contamination-free saturated steam—precisely regulated, emission-free, and with up to 50% redundancy for maximum operational reliability. These units operate using forced circulation technology and allow seamless modulation from 0 to 100%. This enables the steam supply to be precisely adapted to production cycles—an essential advantage in batch production processes such as pasteurization, sterilization, or bottle cleaning. Integration into existing systems is space-saving, as no traditional boiler body is required. An intelligent control system automatically monitors performance, load management, and energy consumption for up to 168 hours. Especially in times of rising energy costs, hybrid systems offer additional flexibility by combining electricity with conventional fuels—making it a worthwhile investment.

Steam at the Push of a Button

The new steam generators also rely on the proven principle of forced circulation technology. Unlike conventional boilers that store and slowly heat large volumes of water, a Clayton steam generator produces steam on demand. At the heart of the electric technology is a forced recirculation system that is precisely tailored to industrial requirements. This new model ensures pure active power and eliminates performance losses for maximum efficiency. Thanks to its well-thought-out design, the use of smaller transformers and cables is possible, significantly reducing infrastructure costs. Heat transfer is achieved via robust stainless steel tube bundle heating elements that are precisely controlled by thyristors. The control system reduces peak current consumption by up to 40% and includes precise regulation of power limits (kW) to ensure optimal performance and adaptability across various applications and industries. The advanced control mechanism guarantees consistent steam production even under fluctuating load conditions. The integrated PLM (Power Load Management) system further optimizes energy use. The result is an extremely energy-efficient process that avoids electricity peaks while achieving optimal performance and minimizing operating costs. Particularly advantageous is the seamless modulation from 0 to 100%, allowing immediate adaptation to changing steam demands. The electric steam generator also produces high-quality 99% dry saturated steam. Optional integrated water treatment and auto-monitoring packages enable continuous operation for up to 168 hours.

EPower™ with Load Management

The new series delivers climate-neutral energy, with no direct emissions at the point of use. This makes it an ideal solution for companies aiming to reduce their CO₂ footprint and meet environmental standards. Thanks to a dual heating element configuration, the system provides 50% redundancy, significantly enhancing its reliability. By eliminating the need for a bulky boiler body, these rapid steam generators are much more compact than traditional units, saving valuable space in production facilities and enabling flexible integration into existing systems.

The E-Series proves especially forward-looking in hybrid systems: the integrated Smart Control allows fully automated energy management that seamlessly switches between gas/oil-fired and electrically powered steam generation. The E-Series’ precise control ensures consistent steam quality and output even under varying load conditions. This consistency is a key advantage for applications requiring sensitive processes and high quality standards. The refined combination of heating elements offers unlimited scalability to meet diverse steam demands—while also ensuring 50% redundancy for maximum operational reliability.

Where Sustainability Pays Off

The E-Series represents a long-term investment in operational infrastructure. By combining proven technology with state-of-the-art electrical systems, this series offers companies a practical way to reduce operating costs, improve their environmental impact, and consistently meet high steam quality requirements. The long service life and low maintenance costs of the E-Series contribute significantly to its economic viability.

In the beverage industry, the V-Series proves especially valuable: from bottle cleaning and pasteurization to the sterilization of production equipment—wherever the highest hygiene standards are required, this technology delivers contamination-free steam of consistent quality. Breweries benefit from precise temperature control during mashing, while dairies appreciate the reliable steam supply for milk processing. Seamless modulation allows the steam supply to be precisely aligned with production cycles—an essential advantage in batch production. Especially in times of fluctuating energy prices, the hybrid operation between electric and conventional steam generation offers economic flexibility that directly impacts production costs.

Beyond the beverage sector, this technology is also used in other industries: pharmaceutical companies rely on its contamination-free steam quality, hospitals use it for reliable sterilization equipment operation, and even data centers benefit from efficient climate control. Additional applications include the chemical, textile, paper, and energy industries.