Productos

Experiencias

Contacto

Calculador de ahorros

Productos

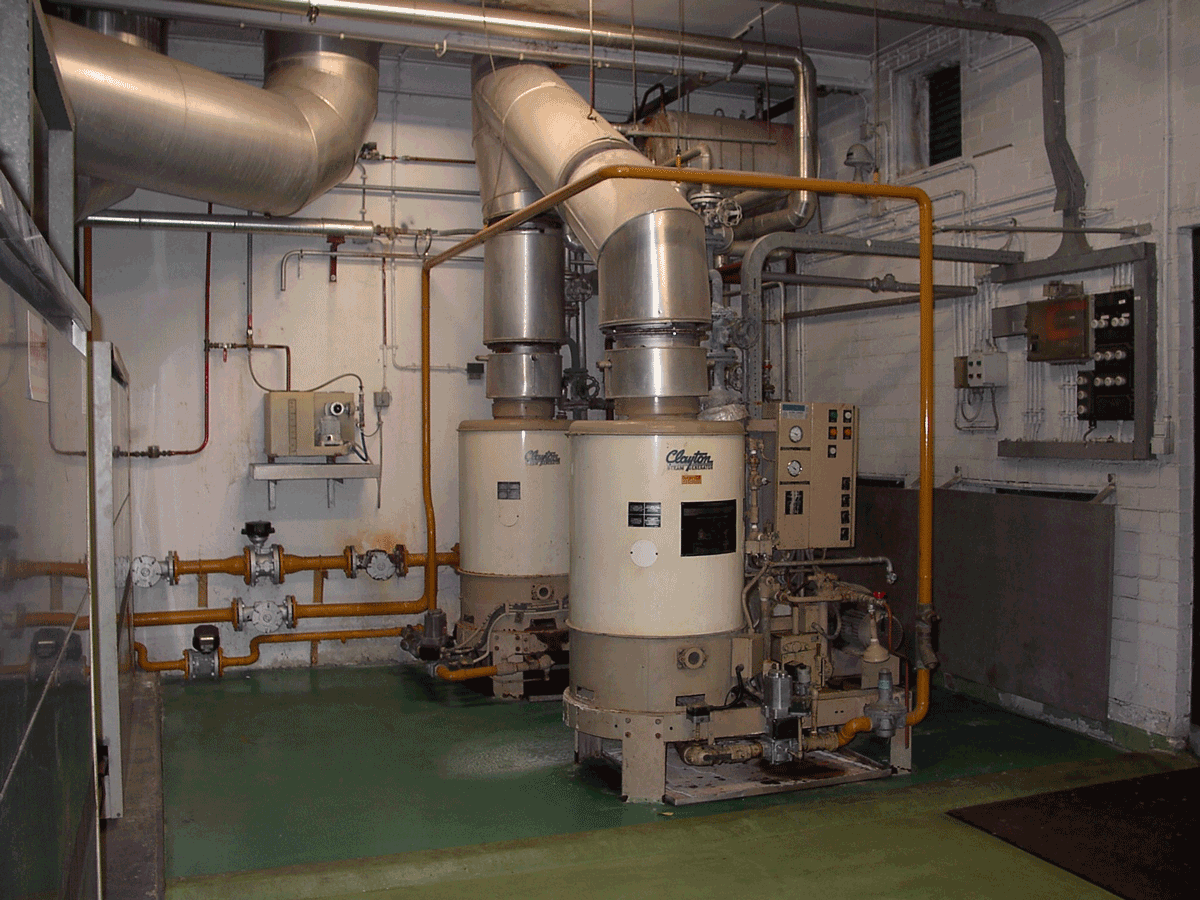

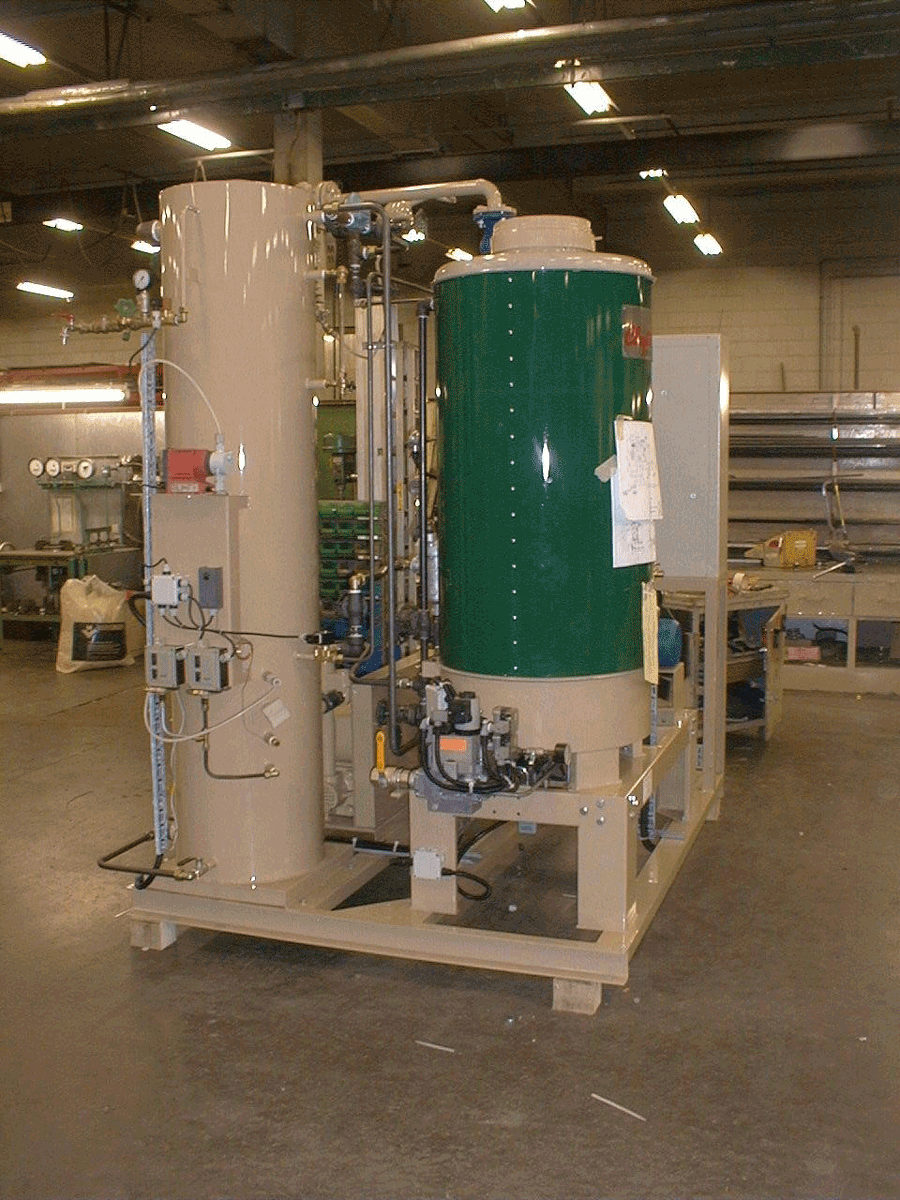

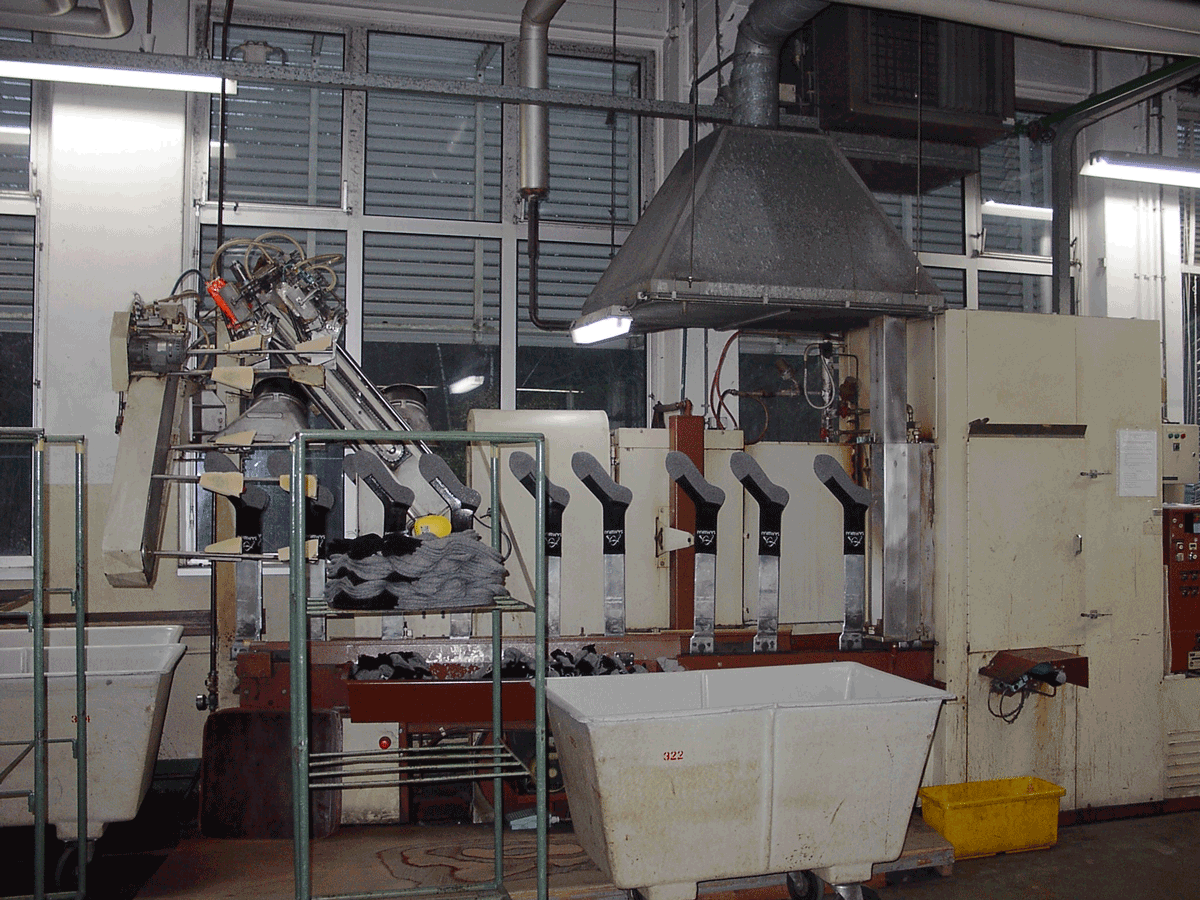

Nuestra gama de productos incluye generadores de vapor saturado de 100kW a 13MW, calderas de recuperación de calor y calderas de vapor sobrecalentado.

Descubre todos nuestros Productos

Descubre más

Descubre más