Detailed information

Boiler house efficiency

Boiler house efficiency indicates in a percentage the amount of useful energy (saturated steam in this case) generated by the steam installation compared to the amount of fuel put into it including the condensate return. It does not consider the potential distribution heat losses in the piping, de-aerator, etc. of the steam installation.

Combustion efficiency

It indicates to what extend the energy contained in the fuel being burned is converted into useful heat. The better your mix of fuel and air is during combustion the more efficient your fuel burning process will be. In the end, exhaust gasses will always generate loss of energy but the better you manage your combustion process, the less energy will be lost. For a new steam generating installation, combustion efficiencies rarely deviate more than 1% when comparing different brands. Therefor, during this life cycle analysis, it is kept the same for the sake of simplicity.

Stack losses (combustion/burner efficiency)

Stack losses correspond to the general known combustion efficiency. It indicates to what extend the energy contained in the fuel being burned is converted into useful heat. The better your mix of fuel and air is during combustion the more efficient your fuel burning process will be. In the end, exhaust gasses will always generate loss of energy but the better you manage your combustion process, the less energy will be lost.

Radiation and convection losses

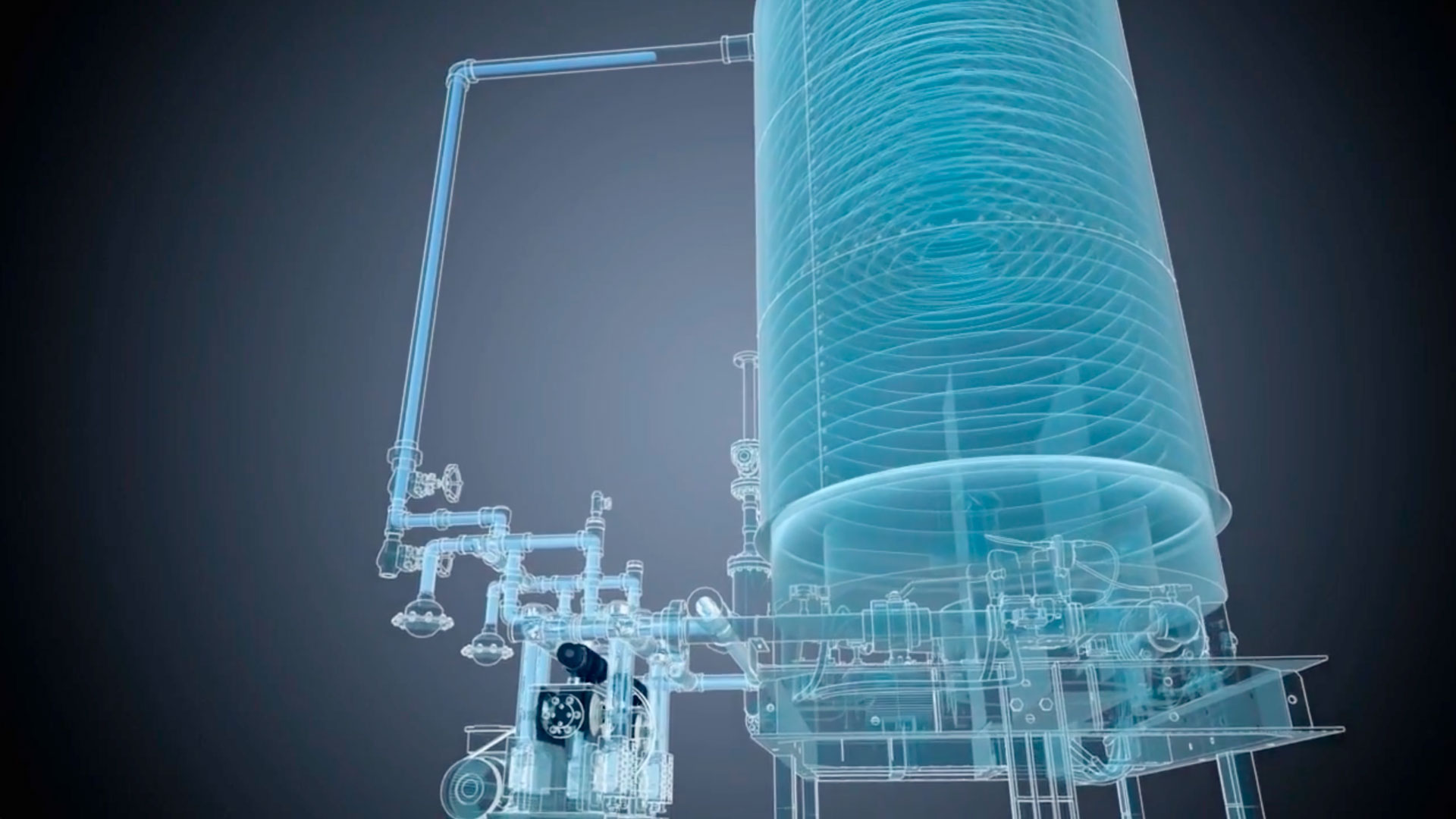

These losses are the result of heat originating from hot surfaces that is lost to its surroundings through radiation and convection. Most commonly they account for a certain percentage of the installed capacity. Traditional boilers which have a large drum lose a lot of energy to its surroundings especially when the unit is working at lower loads. Clayton’s unique compact watertube construction design makes it so that these losses are neglectable in comparison.

Starts

Each time a cold start is initiated, a boiler or steam generator needs time to reach the required temperature and pressure before it is able to produce steam. Consequently, the larger the boiler water content, the more energy it takes to produce steam. The volume of water in a Clayton steam generator is significantly less than traditional boilers hence its start-up time is quite substantially shorter and its start-up losses are therefore smaller.

Blow down losses

Having a periodic purge stream, known as blow down, of the feedwater to control/manage the total dissolved solids (TDS) content is essential for an optimal working of any kind of boiler. However, heat, water and chemicals are lost when such a blowdown is carried out. Clayton’s steam/water separator design enables a blowdown on a highly concentrated water stream. A Clayton steam generator needs to blow down up to 7 to 8 times less than conventional boilers therefore limiting the losses of energy, water and chemicals.

Carrying condensate

Dry steam is absolutely essential when using steam as a heat source. The reason behind this is that it is the latent heat of the steam that will be exchanged in heat exchangers at the customer. Any excess water that will be carried by the steam leaving the boiler will not participate in the heat transfer and can therefore be regarded as lost energy. If steam carries 10% water then that steam is regarded as 90% dry. Steam created by standard boilers and steam generators are around 93-96% dry and special equipment is needed to achieve dryer conditions. Clayton’s patented high-quality steam/water integrated separator, makes it possible to guarantee a dryness of 99.5% at any possible load and load-increase.

Load fluctuations

Steam demand is more often not stable and can fluctuate to quite an extend. On that account it is crucial that the boiler or steam generator is able to modulate in load in such a way to satisfy these fluctuations. Due to the small water content in Clayton steam generator, the unit can rapidly respond to strong changing steam demands. Moreover, Clayton units are also able to modulate on the burner, blower and pump to guarantee a completely stable steam production and offer “steam-on-demand”

Stand-by losses

More often steam demand is not continuous and comes in cycles. To avoid the long cold start-up times of conventional boilers, they are kept in hot- or warm stand-by. Any energy used to keep the unit at a certain pressure/temperature during a stand-by results in that energy being lost. Due to the fast start-up procedure of a Clayton steam generator, it is not needed for it to be held in hot-standby and can simply be shut down to minimize energy losses.